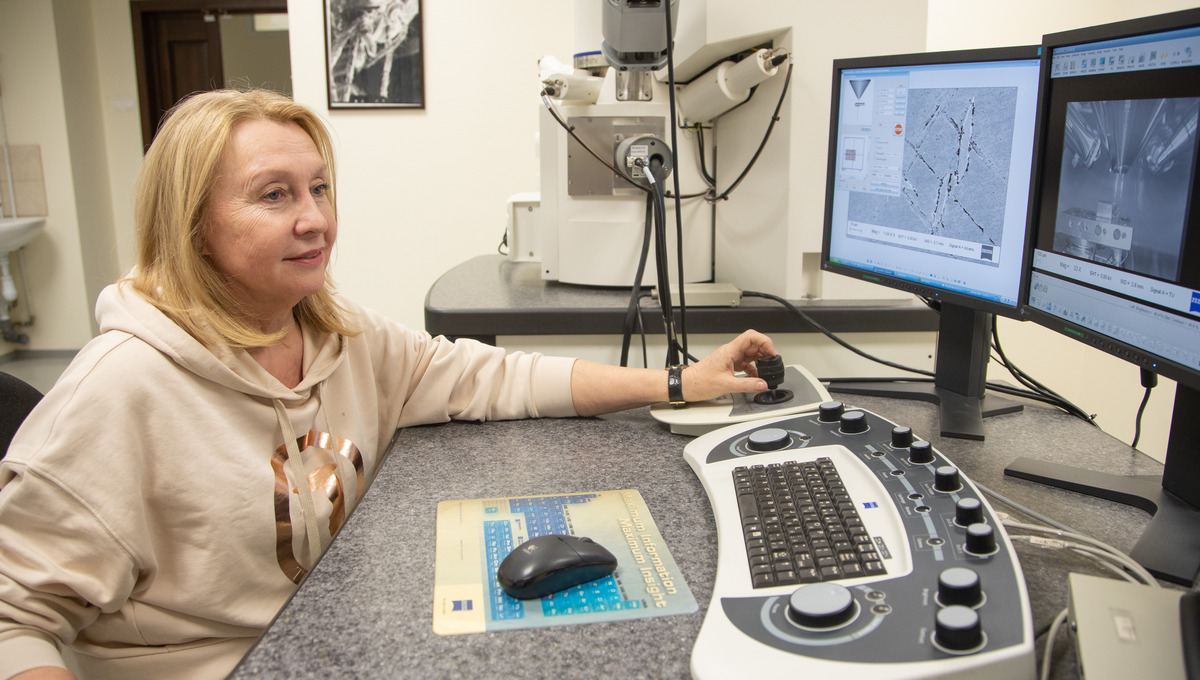

The properties of the material developed under Svetlana Rempel's guidance are tested using a scanning microscope. Photo: Ilya Safarov.

Ural scientists have used a new method to analyze the material for bone implants. With its help it is possible to regulate the dissolution rate of the implant in the area of bone damage. A description of the experiments and the results of the study are published in the journal Ceramics International.

Synthetic bioactive hydroxyapatite (HA) is a material that is used to make bone prostheses and implants that promote new bone growth. It is widely used in traumatology, dentistry, maxillofacial surgery and cosmetology. Previously, scientists found that the addition of titanium monoxide gives the material strength and preserves the ability of HA to integrate into the body without causing side effects. However, the resulting nanocomposite (multicomponent nanomaterial) requires a detailed study of the interaction between the additive and its matrix at all stages of synthesis, as well as the effect of this interaction on the properties of the final product. This is necessary to improve the reconstruction of damaged bones. The better the implant binds to the bone tissue, the more effective the healing of damaged areas.

"By investigating the thermochemical and physical-chemical properties of the nanomaterial, we can achieve some of the desired implant properties. For example, the dissolution rate of the implant material in the bone defect area. It can be regulated by changing the calcium phosphate content in the nanocomposite, which, as we have shown, depends on the stoichiometry of titanium monoxide additives. This will create conditions for the normal course of the regeneration process and structural reorganization of the bone in the contact zone with the implant", explains Svetlana Rempel, leading researcher of the Institute of Solid State Chemistry of the Russian Academy of Sciences (UB), associate professor of physical methods and quality control devices of UrFU.

To study the properties of the nanocomposite, the scientists first used the method of synchrotron X-ray diffraction. Synchrotron radiation showed the greatest accuracy and efficiency in analyzing the material in real time.

"With this method we studied changes in the properties of the nanomaterial under the influence of different temperatures - from ambient temperature to 900 °C. Unlike other methods, in situ study on a synchrotron radiation source allowed to determine the temperature of formation of different phases during heating and cooling of nanocomposites, get information on the size of the particles, to make sure that all components are biocompatible, as well as find indirect evidence of a partial replacement of calcium for titanium in the composition of hydroxyapatite," says Svetlana Rempel.

It should be noted that scientists of the Ural Federal University and the Ural Branch of RAS (Ekaterinburg) with colleagues from Graz University of Technology (Austria) and the Siberian Branch of RAS (Novosibirsk) worked on the creation and study of biocompatible material containing hydroxyapatite and titanium monoxide. The development is patented. The experiment of synchrotron irradiation of material was carried out in the Siberian Center for Synchrotron Radiation at the Novosibirsk accelerating complex VEPP-4 - VEPP-2000. The study was supported by the Russian Foundation for Basic Research (Project No. 20-03-00675).

Reference

X-ray diffraction (XRD) is an analytical technique that provides information on the structure and phase composition of crystalline materials. Synchrotron radiation is produced in rotating magnets mounted in a vacuum chamber, inside which a narrowly directed beam of electrons moves at near-light velocity. During the rotation - under the influence of the magnetic field - the flying electrons emit beams of photons tangentially to the orbit in a wide spectrum, the maximum of which falls in the X-ray range.Ural Federal University is one of the leading universities in Russia that celebrated its 100th anniversary in 2020. UrFU is located in Yekaterinburg, the capital of the World Summer Student Games 2023. The University has initiated the establishment of the Ural Interregional Research and Education Center — ‘Advanced Industrial Technologies and Materials’ and is its project office designed for solving tasks of "Science" National Project.

urfu.ru