© Wiley-VCH, re-use with credit to 'Angewandte Chemie' and a link to the original article.

Whether as packaging or toys, mulch films or cars, plastics based on petrochemicals are ubiquitous—demand is rising, and so are the piles of garbage. Bioplastics based on natural materials like starch, or synthetic biomaterials like polylactic acid, have exhibited inadequate durability, biocompatibility, and/or biodegradability in most cases. In addition, they often require complex, energy-intensive processing methods and toxic chemicals.

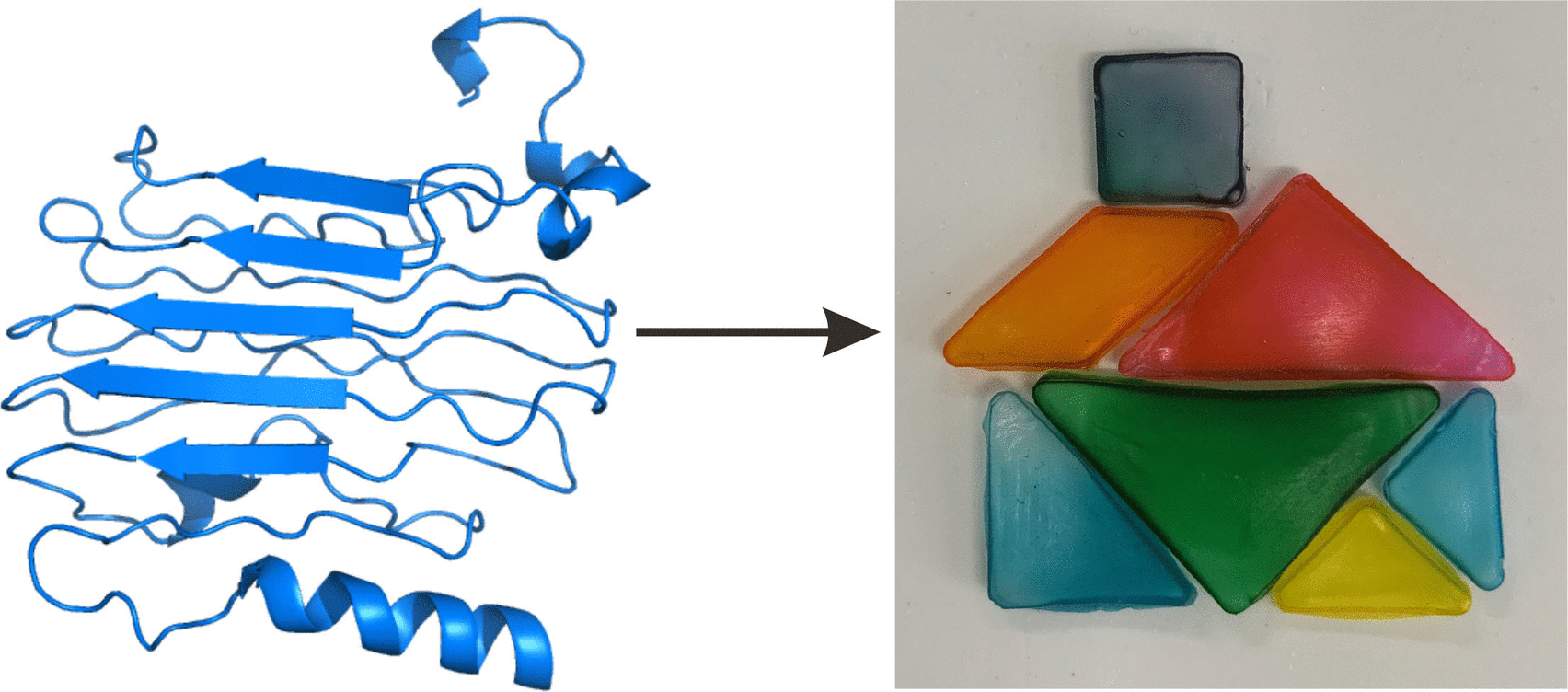

A team led by Jingjing Li and Yawei Liu (Chinese Academy of Sciences, Changchun, China), as well as Bo Wei (First Medical Center of PLA General Hospital) have now introduced novel bioplastics with properties that can be tailored according to need. To do this they developed two lysine-rich proteins and produced them in bacterial cultures: “ELP” is a polypeptide similar to the connective tissue protein elastin. It does not have defined folding, which leads to toughness and elasticity. “SRT” consists of ELP plus crystalline segments of a squid protein with a β-sheet structure.

ELP (or SRT) is crosslinked with a polyethylene glycol (PEG) derivative by way of its lysine amino side-groups. (PEG is used in pharmaceuticals, among other things.) If the crosslinking occurs in water, the material can then simply be dried in a mold. The result is a tough, transparent, solvent-resistant bioplastic. Its mechanical properties can be varied by changing the proportion of PEG. This allows for the production of bioplastics with high mechanical strength at room temperature in any shape desired, and without toxic chemicals or complex processing steps such as liquefaction, extrusion, or blow molding. Their breaking stress exceeds those of many commercial plastics. One problem left is that they swell in water.

If ELP is crosslinked in a water/glycerol solution, the material gels into soft, elastic bioplastics. The team also used wet spinning to produce biofibers that are as strong as some biotechnological spider silks. The natural enzyme elastase completely degrades all of the new protein-based bioplastics.

It is conceivable to make toys with this new, nontoxic bioplastic that can be dyed with food coloring. This material may also be used to seal wounds as it has hemostatic effects. Implants were completely broken down within a few weeks.

To store information, ELP could be polymerized together with peptides that have been programmed with codes by means of their specific amino acid sequences. The information could be read back through sequencing. This would allow for higher information density than is possible with DNA data storage.

(3094 characters)

About the Author

Dr. Yawei Liu is an assistant research scientist at the Changchun Institute of Applied Chemistry, Chinese Academy of Sciences. Her main specialty is biomaterials technology, and the materials design to broaden the application of biomaterials, especially engineered proteins.

Copy free of charge—we would appreciate a link to or transcript of your article. The original articles that our press releases are based on can be found in our online pressroom at pressroom.angewandte.org

newsroom.wiley.com.